1. Description

This series of condensation-cure (tin-catalyzed) silicone is a high-hardness mold rubber. It consists of a white or translucent Part A base and a transparent to slightly yellowish Part B curing agent. When mixed in a weight ratio of 100A:3B, they cure at room temperature into a high-hardness elastomeric material. This hard silicone rubber exhibits excellent resistance to stress and is well-suited for applications where dimensional stability and rigidity are essential. However, it's important to note that compared to medium-hardness tin-cured silicone, this hard silicone is relatively more brittle.

Based on the properties of tin-catalyzed silicone, it is recommended to work with it within a temperature range of 20 to 30°C (68 to 86°F). Curing becomes challenging below 10°C (50°F), so it is important to maintain suitable temperatures. If you decide to apply heat to accelerate curing, it is not advisable to exceed 45°C (113°F). Additionally, you can adjust the operation time and curing time suitable for your project by adjusting the ratio of part A and part B (100:2-100:4).

2. Feature

- High hardness, takes a low compression set.

- Withstands temperatures up to 200°C (392°F).

- Low shrinkage (≤0.03%).

- Excellent mold release, allowing for easy release without sticking.

- Simple operation, quick curing at room temperature.

3. Application

This series of silicone rubber has high replication accuracy, dimensional stability, and mechanical strength, making it especially suitable for applications that require high-hardness mold making. It is widely used in rapid prototyping and recommended for prototype mold-making applications in the electronics and automotive industries, such as television sets, home appliances, mobile phones, copiers, console boxes, radiator grills, lamp housings, and more.

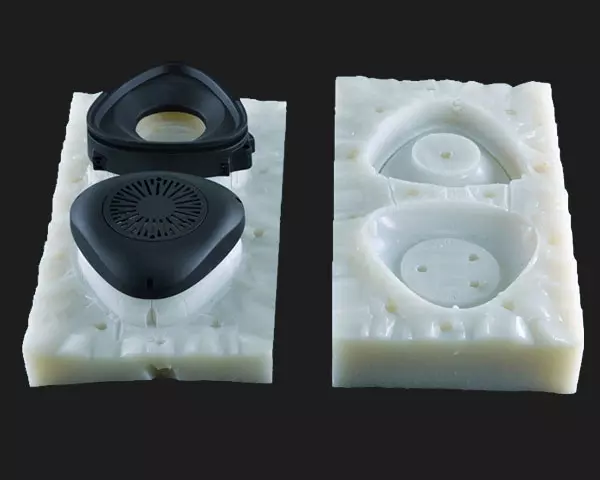

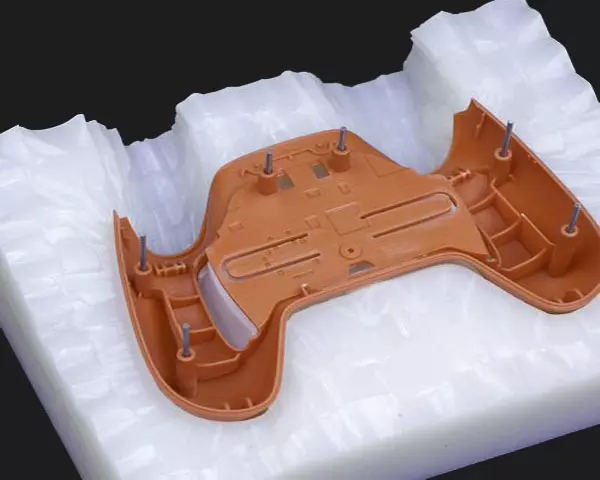

Prototype Vacuum Casting

Thin Shell Prototyping

Cement Silicone Mold

Ceramic Silicone Mold

4. Attention

- It is recommended to use Part A and Part B of the same model and lot number. If a different model or lot number is used, its suitability should be determined by testing.

- Parts A and B should be mixed properly and in the correct proportions. Using too much tin curing agent to accelerate curing may shorten the mold's service life, leading to brittleness and deterioration.

- If the tin-cured silicone material appears gummy or uncured after the recommended curing time, it is necessary to investigate the cause, which may include temperature, mixing ratio, whether it was stirred evenly, and whether other substances were added.

- Tin-cured silicone molds may exhibit higher shrinkage over time, depending on the material being cast into the mold, mold configuration, and other variables.

5. Safety

- When using tin-cured liquid silicone, it is important to ensure adequate ventilation. During curing, the following gases are generated depending on the cure type: acetic acid type (acetic acid), alcohol type (methanol), oxime type (methyl ethyl ketone oxime - MEKO), and acetone type (acetone). If ventilation is inadequate, respiratory protection should be worn. Avoid continuous inhalation of vapors and spray mist, and take precautions to prevent skin and eye contact. Wear safety glasses with side shields and use liquid-tight gloves, such as butyl rubber, neoprene, or PVC, to minimize the risk of contamination. Remember to wash your hands thoroughly after use.

- Over time, tin-cured silicone appliances and molds may leach and become brittle due to the catalyst's instability. As a result, these products are intended for industrial use only and should not be used in applications that require a long shelf life or direct contact with the skin. For food contact applications, platinum-cured silicone rubber should be used instead.

- Under normal storage and handling conditions, these products are stable in airtight containers at room temperature and will not undergo hazardous reactions.

- Please keep these products out of the reach of children.

- First Aid Measures:

- Skin Contact: If the product comes into contact with the skin, wash thoroughly with soap and water.

- Eye Contact: In case of contact with the eyes, flush them with plenty of water while lifting the upper and lower eyelids. If irritation persists, seek medical attention.

- Inhalation: Remove the individual from the contaminated area and provide fresh air. If breathing has stopped, administer artificial respiration and seek immediate medical attention.

- Ingestion: If ingested, do not induce vomiting unless instructed by a physician. Never give anything by mouth to an unconscious person.

Please note that these measures are general guidelines. In case of an emergency, always consult a medical professional or seek immediate medical attention.

6. Storage

The shelf life of the product is 12 months from the date of production. Storing the material at higher temperatures can also reduce the available shelf life of unused materials. These products have a limited shelf life and should be used as soon as possible.

Containers that have been opened must be carefully sealed to prevent leakage. Store the material in a cool, dry, well-ventilated place, away from heat, direct sunlight, strong oxidizers, and any incompatible substances such as strong bases and acids.