In the field of silicone mold making, pour-on and brush-on technologies are two popular mainstream methods. Each technology has its own advantages and disadvantages, suitable for different mold-making projects. This article aims to explore the key differences between pour-on and brush-on to help you evaluate the most suitable process for your project.

Pour-on Technology

Pour-on technology is the simplest mold-making process, suitable for models with simpler shapes. It is applicable for producing both single-piece and two-piece silicone molds.

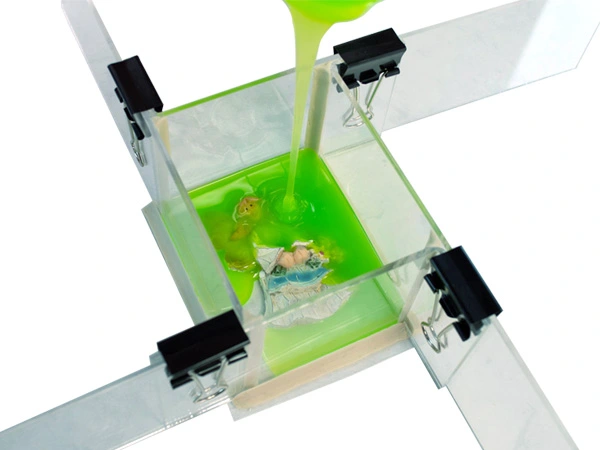

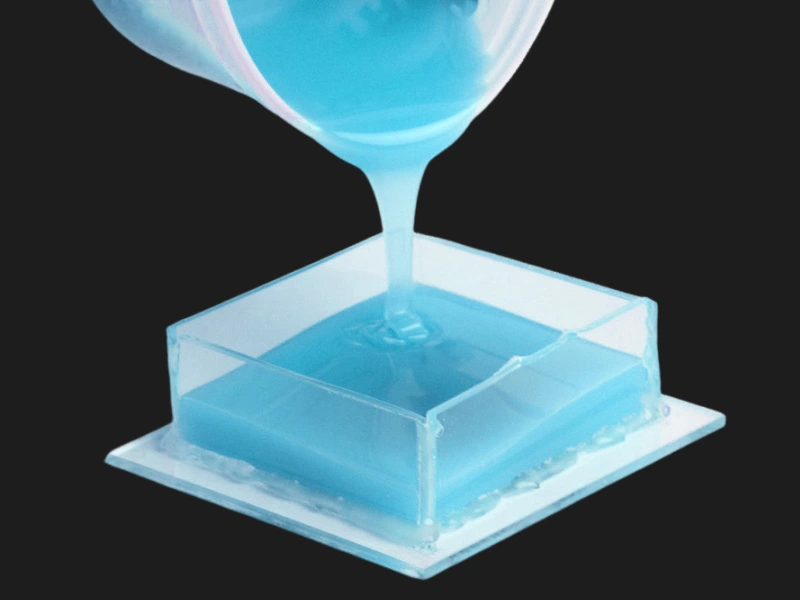

Creating molds with pour-on technology requires building a sealed mold box. The shape of the mold box, along with the master model's shape, determines the final mold's form. Ideally, there should be a clearance of about 0.5 cm from the edges of the master model to the mold box, defining the thickness of the silicone mold. Compared to brush-on, the pour-on process is simpler and more direct, taking less time but using more material.

pour-on technology

pour-on technology

Brush-on Technology

Brush-on technology is particularly suitable for master models with rich texture details or deep undercuts, such as sculptures or character models. This process involves applying silicone in multiple layers over the model, layer by layer, until the desired thickness is achieved. Although brush-on is time-consuming and labor-intensive, it is more economical in terms of material use.

When applying the first layer of silicone, the thickness of this initial application need not be considered; the focus should instead be on ensuring complete coverage, especially over areas with undercuts. After the first layer has initially cured, apply a second layer. A layer of inelastic gauze can be added between the two silicone layers to enhance the mold's tear resistance. Typically, applying 2-4 layers is appropriate to avoid making the silicone layer too thin, which could lead to the mold tearing easily.

brush-on technology

brush-on technology

Conclusion and Recommendations

The detailed analysis above highlights the differences between the two mold-making techniques. The choice of technique depends on the specific requirements of the project. On average, the material cost of pour-on is about 15% higher than that of brush-on, but its time efficiency is 40% higher. By comparing the characteristics of these two methods, you can gain a clearer understanding of material costs and time costs, assisting you in selecting the technology that most suitably fits your specific project requirements.