This tutorial will demonstrate how to create a two-part silicone mold and cast polyurethane resin to replicate a glass bear craft. The tutorial is simple and easy to understand, making it perfect for beginners.

Tools & Materials

- Original model: glass bear

- Platinum-cured silicone

- Polyurethane resin + pigment

- Sulfur-free clay

- Plastic cups + stirring sticks

- Hot glue gun

- Bolts

- Mold release agent

- Mold box

- Ruler

Step 1: Secure the Master Model

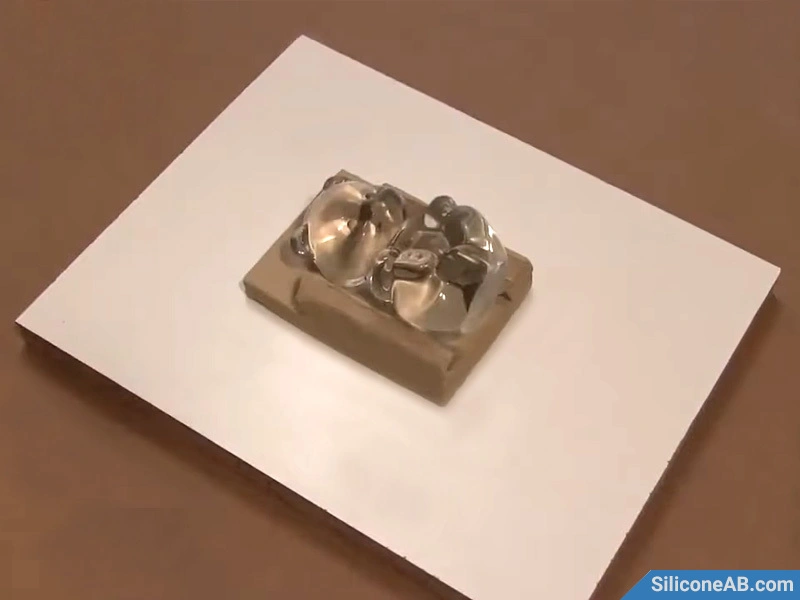

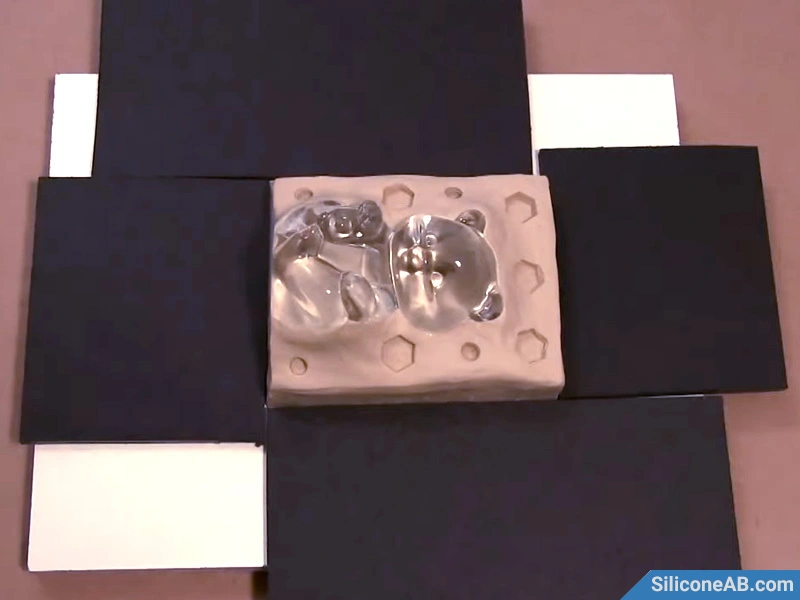

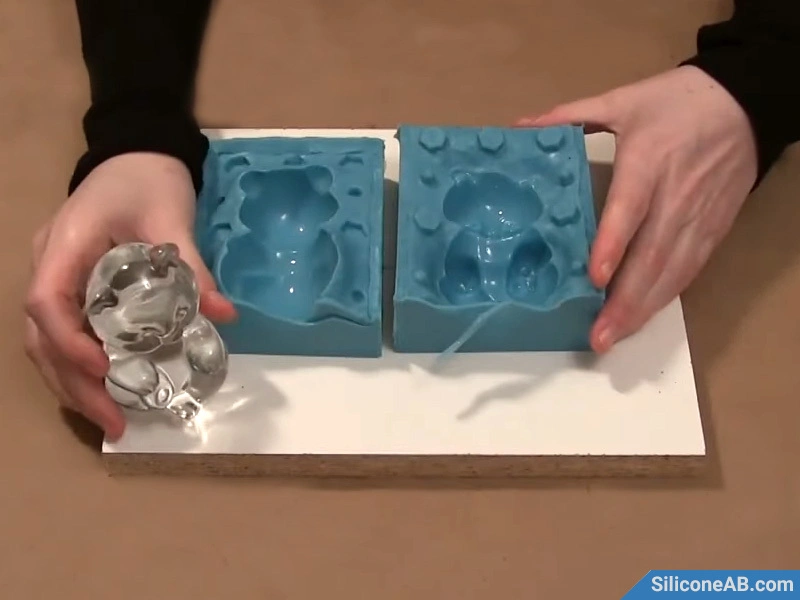

According to the shape of the glass bear model, create a parting line using sulfur-free clay, embedding part of the model in the clay. Note: Ordinary clay contains sulfur, which inhibits the curing of platinum-cured silicone.

Step 2: Set Positioning Holes

Use bolts to create positioning holes in the clay to ensure the two parts of the silicone mold align tightly, producing a seamless casting.

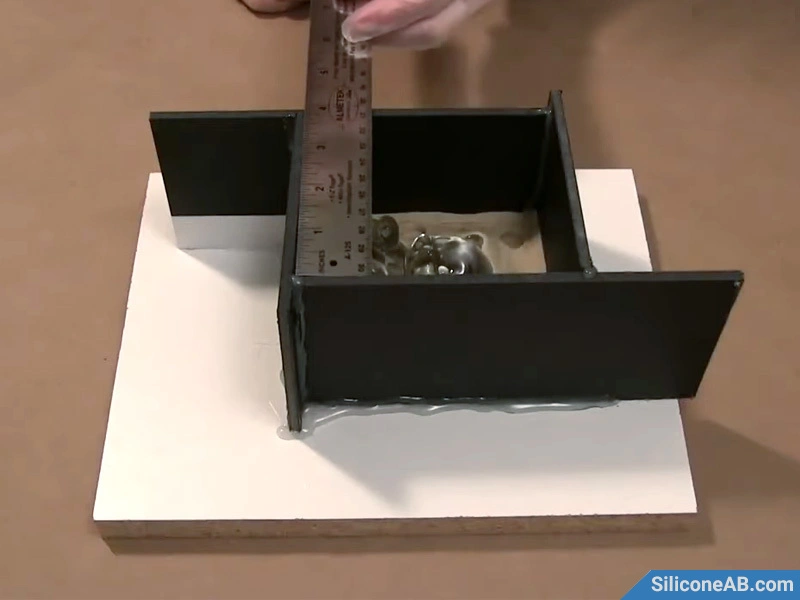

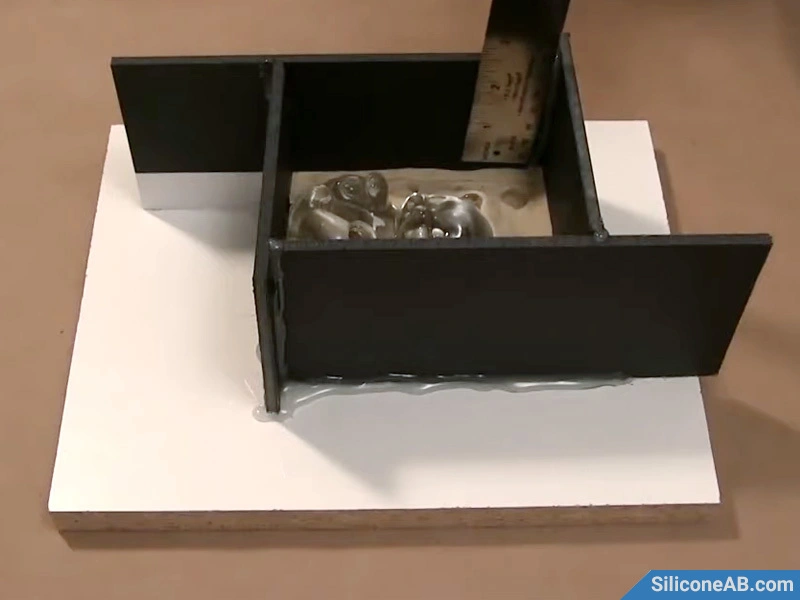

Step 3: Build the Mold Box

Construct the mold box and seal all seams with hot glue to prevent liquid silicone from leaking out.

Step 4: Calculate the Required Amount

Measure the length, width, and height of the mold box with a ruler, then calculate the required amount of silicone using the formula: weight = density × volume. It is recommended to use our website's silicone amount calculator.

Step 5: Prepare the Silicone

Prepare the silicone according to the calculated amount, weighing out parts A and B of the platinum-cured silicone in a 1A:1B ratio (by weight or volume) and mixing them thoroughly. Usually, 20-30 Shore A hardness silicone is chosen, depending on the size of the master model.

Step 6: Vacuum Degassing

Due to air incorporation during mixing, it's recommended to use a vacuum pump to degas the mixed silicone to avoid bubbles in the silicone mold.

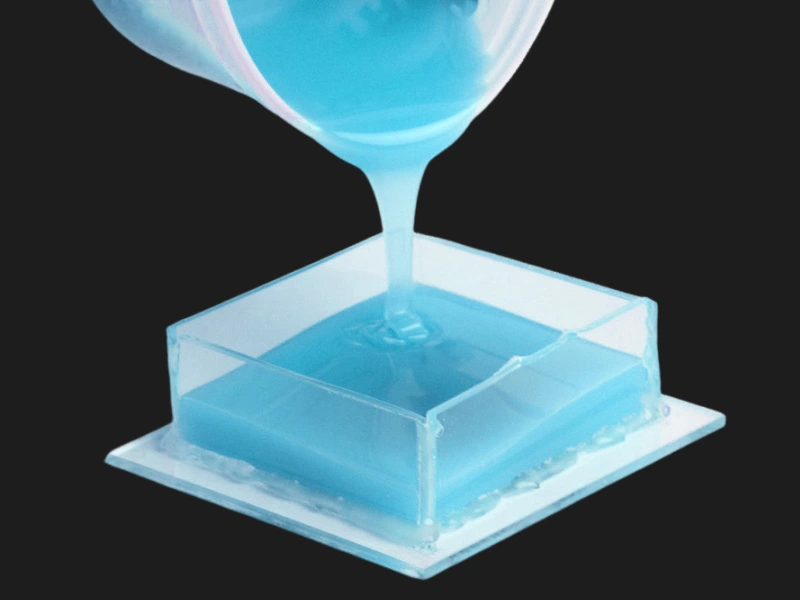

Step 7: Pour the Silicone

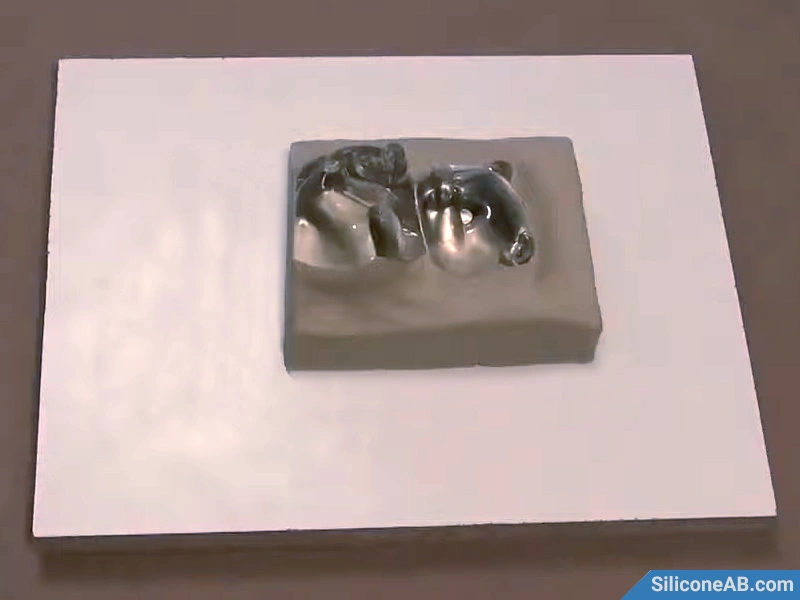

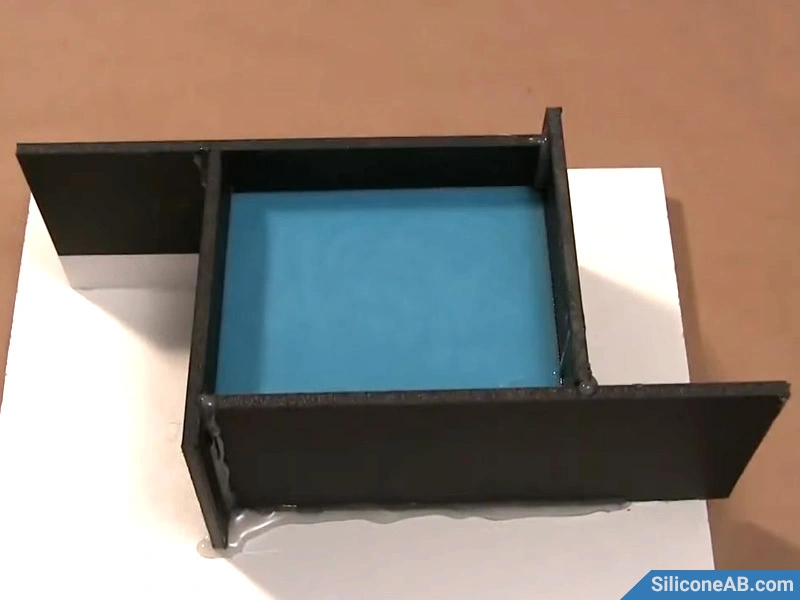

Slowly pour the degassed silicone into the lowest point of the mold box, allowing it to flow naturally until it covers the model. Pouring slowly in a thin stream helps reduce bubble formation.

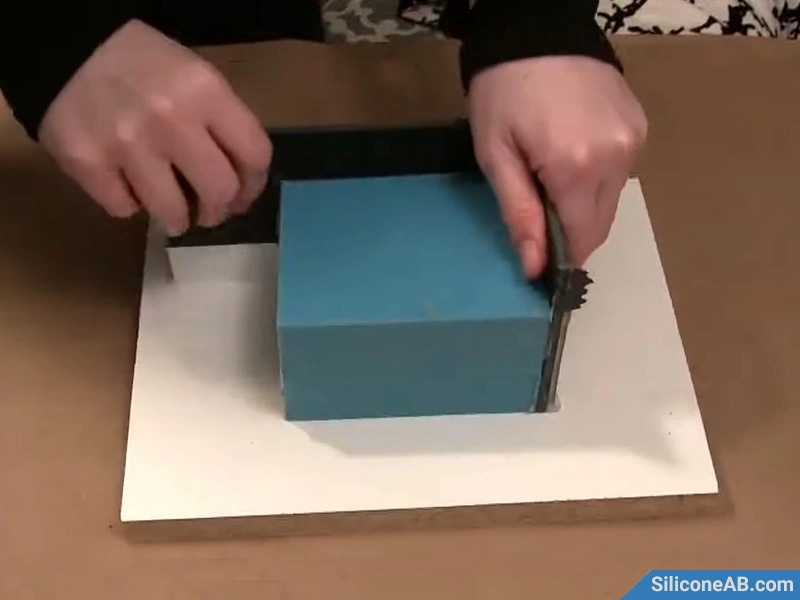

Step 8: Remove the Mold Box

The silicone curing time varies by brand and ambient temperature, typically 3-5 hours. Once fully cured, remove the mold box.

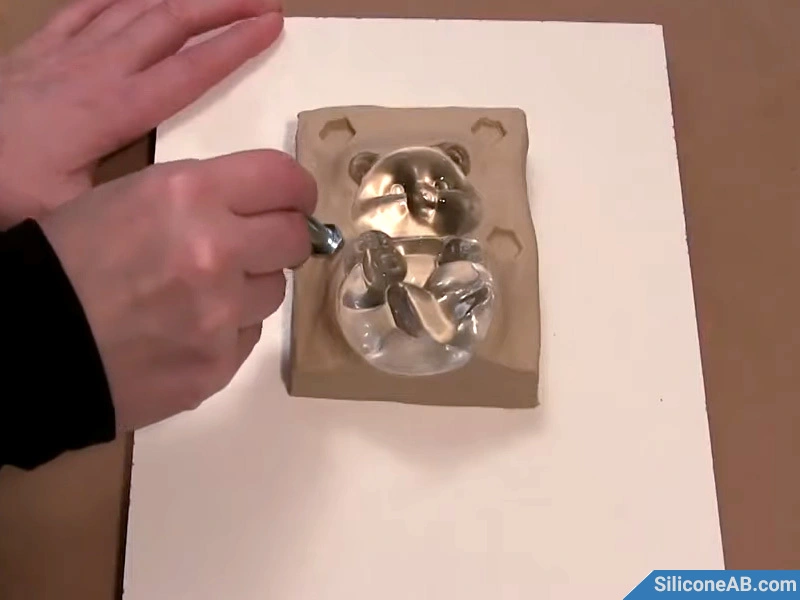

Step 9: Remove the Clay

Carefully peel the clay away from the model and clean the model with alcohol. Do not separate the model from the silicone mold at this stage.

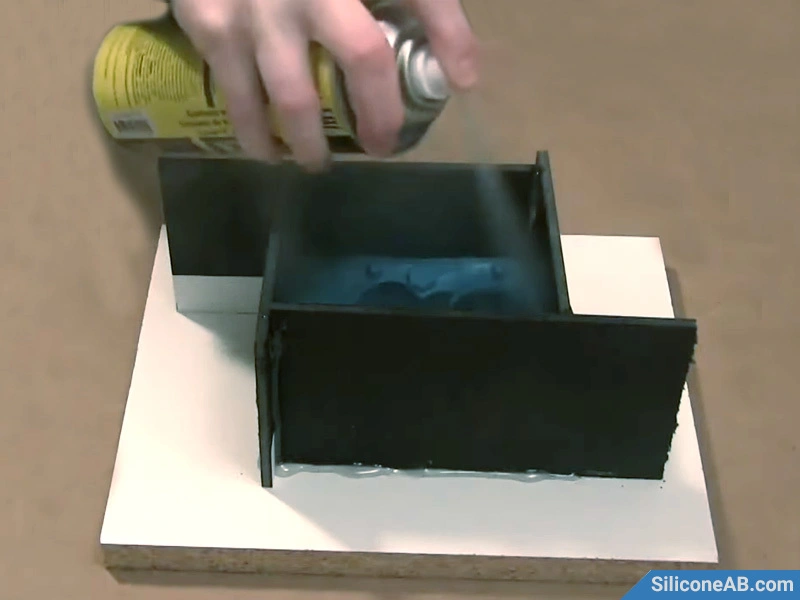

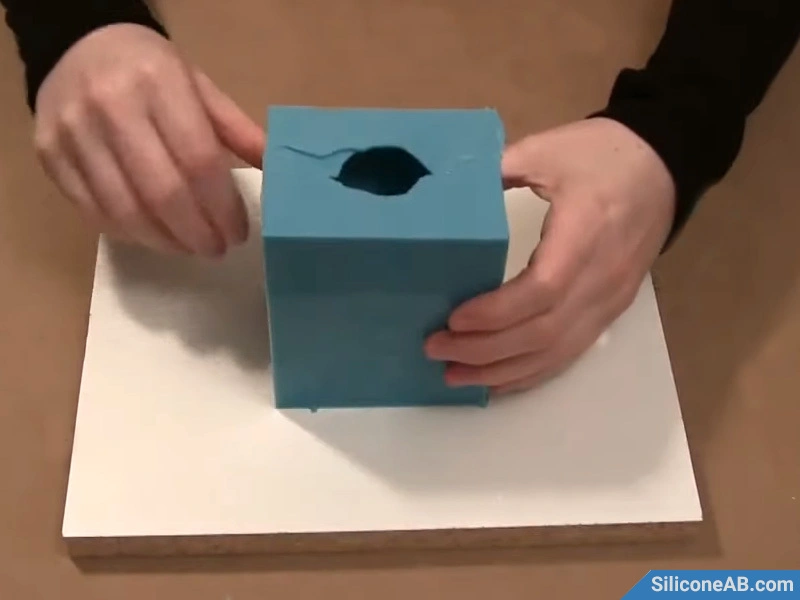

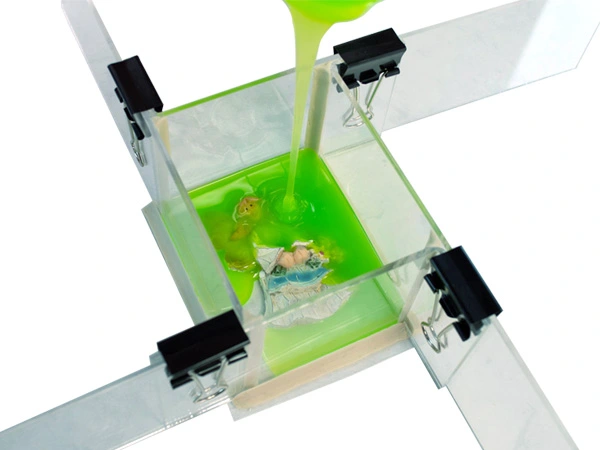

Step 10: Rebuild the Mold Box

Reassemble the mold box and spray it with a mold release agent. The release agent is essential to prevent difficulty in separating the silicone after curing.

Step 11: Make the Second Part

Repeat steps 5 to 8, mixing and pouring silicone to create the second half of the mold.

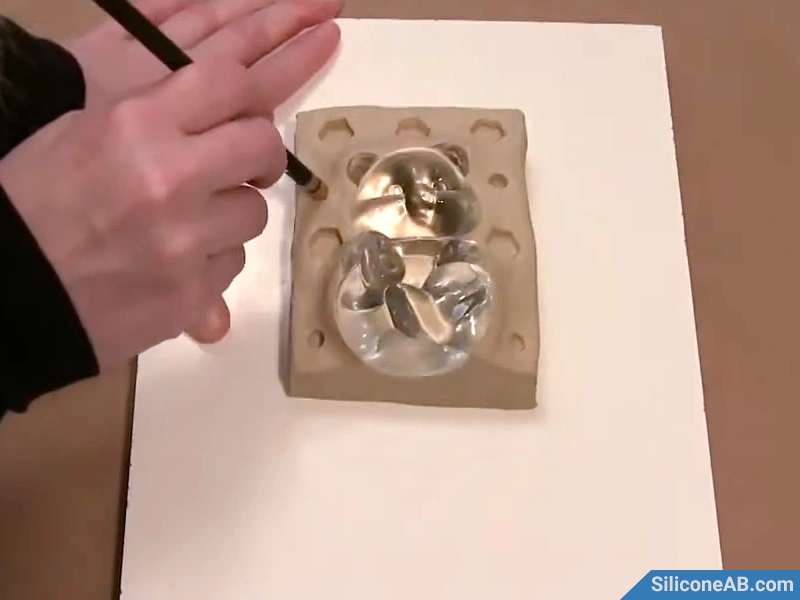

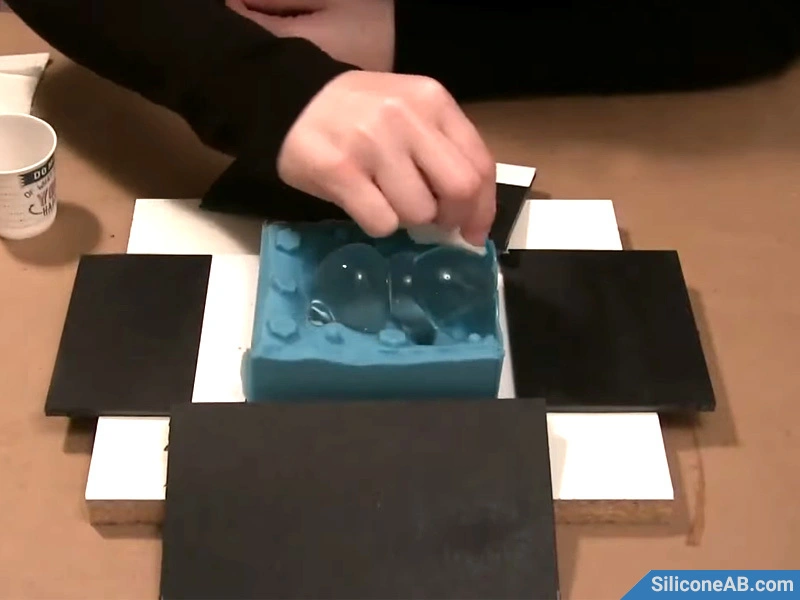

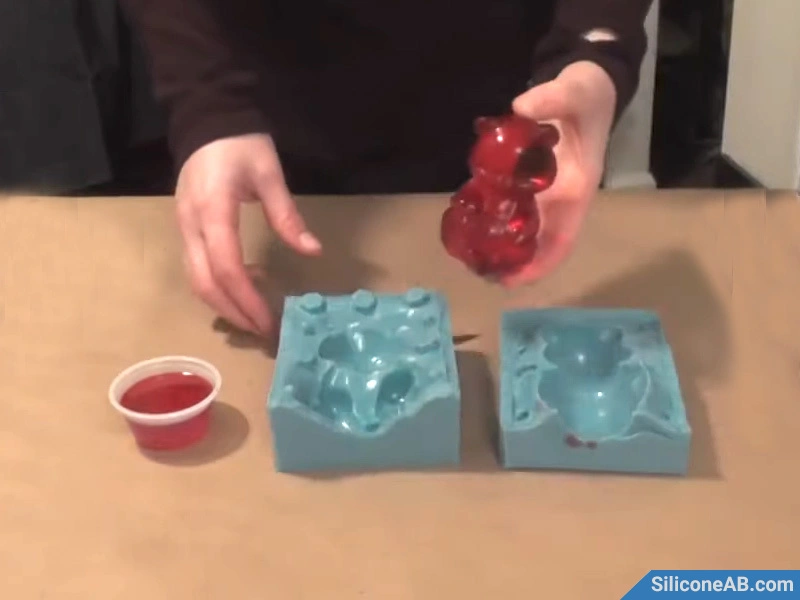

Step 12: Separate the Mold

Carefully separate the two parts of the silicone mold and remove the original glass bear model. Thanks to the excellent release properties of platinum-cured silicone and the release agent, this should be an easy process.

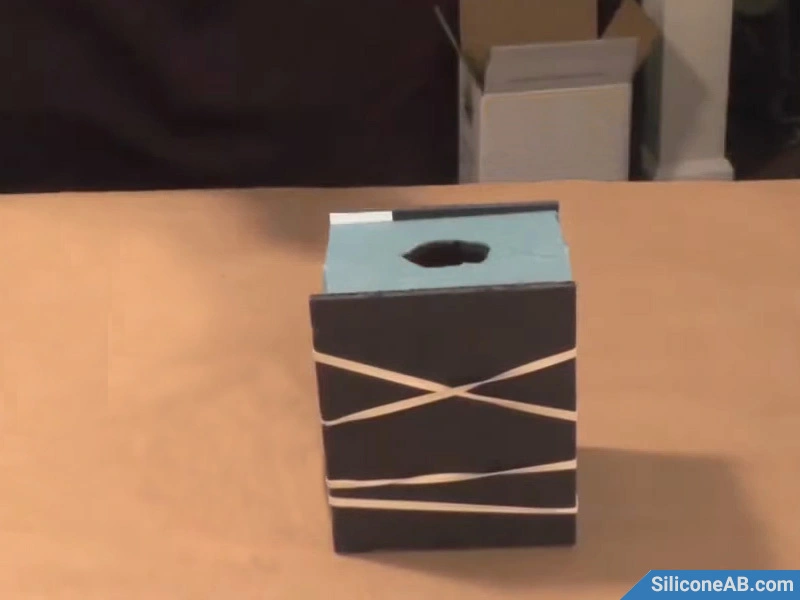

Step 13: Assemble the Mold

Reassemble the two parts of the silicone mold, securing them with rubber bands. The positioning holes created in step 2 will ensure proper alignment. For larger molds, use non-elastic straps to prevent deformation during casting.

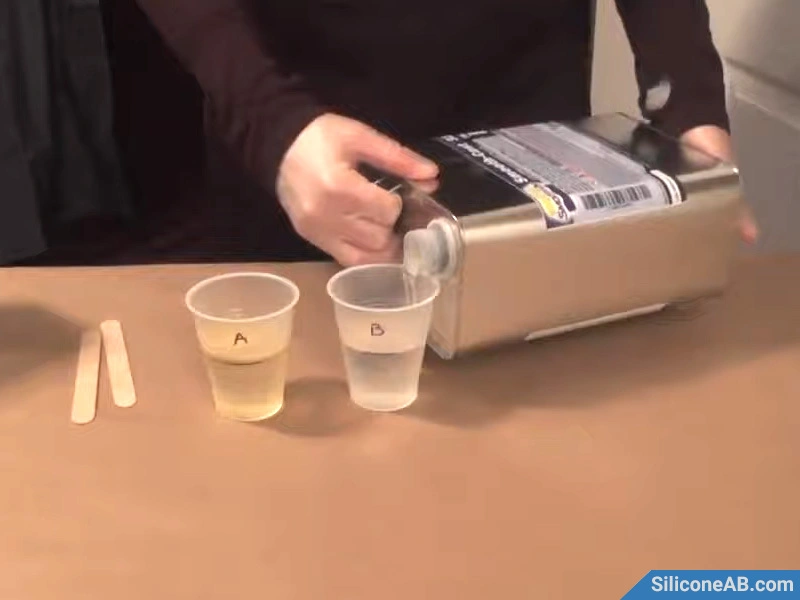

Step 14: Prepare the Resin

Weigh parts A and B of the polyurethane resin in a 1A:1B ratio (by weight or volume) and add the desired pigment, mixing thoroughly.

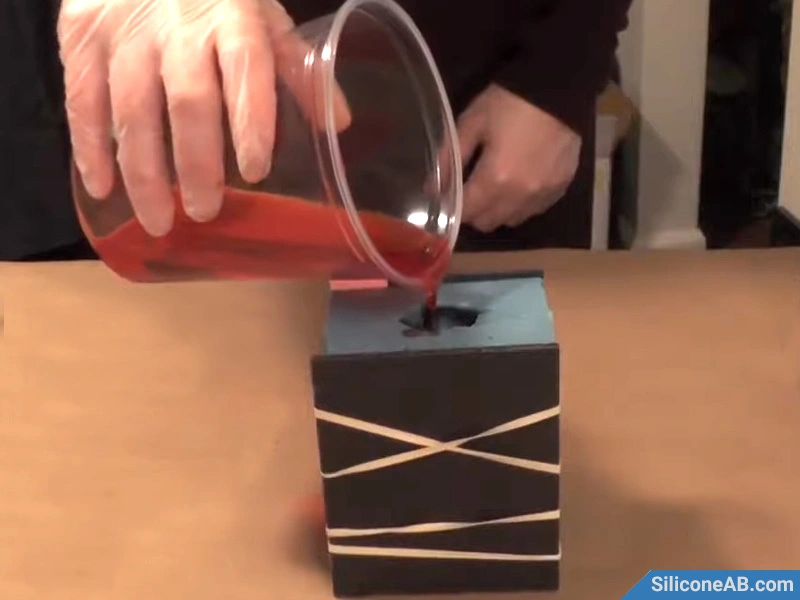

Step 15: Pour the Resin

Pour the mixed polyurethane resin into the mold. Fill about a quarter of the mold and then vibrate or rotate it to ensure the resin covers every detail of the model. Polyurethane resin has a short working time, so mix and pour quickly.

Step 16: Remove the Mold

To check if the resin is cured, leave a small amount in a plastic cup and touch it to test its state. If cured, you can demold the cast resin product.

By following these steps, you can easily create high-quality two-part silicone molds and replicate exquisite glass bear crafts. We hope this tutorial is helpful to you, and happy crafting!