RTV-2 liquid silicone raw materials can be mixed in specific proportions and formulas by combining Part A and Part B to obtain elastic materials with different hardness levels. For beginners or those without a hardness tester, it might be challenging to assess the exact hardness of silicone. Below is a list of common materials in everyday life along with their hardness levels for your reference.

![]() silicone hardness

silicone hardness

| Shore Hardness | Item | Photo |

|---|---|---|

| 10 Shore 00 | Marshmallow |  marshmallow marshmallow |

| 10 Shore 00 | Gummy Bear |  gummy bear gummy bear |

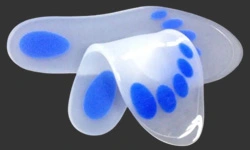

| 30 Shore 00 | Gel Shoe Insole |  gel shoe insole gel shoe insole |

| 20 Shore A | Rubber Band |  rubber band rubber band |

| 30 Shore A | Mouse Pads |  mouse pads mouse pads |

| 40 Shore A | Silicone Pacifier | |

| 50 Shore A | Rubber Stamps |  rubber stamps rubber stamps |

| 55 Shore A | Pencil Erasers |  pencil erasers pencil erasers |

| 60 Shore A | Tire Tread |  tire tread tire tread |

| 70 Shore A | Shoe Heels |  shoe heels shoe heels |

| 80 Shore A | Leather Belt |  leather belt leather belt |

| 90 Shore A | Phone Cord |  phone cord phone cord |

| 50 Shore D | Golf Ball |  golf ball golf ball |

| 60 Shore D | Shopping Cart Wheel |  shopping cart wheel shopping cart wheel |

| 80 Shore D | Hard Hat |  hard hat hard hat |

In almost all applications of RTV-2 silicone rubber, evaluating the hardness or flexibility of the silicone is crucial. Whether you are manufacturing delicate thin-walled components or creating cast molds that need to withstand repeated use, choosing the appropriate hardness of silicone is paramount.

Generally, silicone with lower hardness is more prone to demolding from the mold. If your mold or casting requires flexibility, high elasticity, or if your model has intricate undercuts, choosing a low-hardness silicone material is an ideal choice. However, it is important to note that low-hardness silicone may exhibit reduced tear strength after curing and carries the risk of deformation. Careful handling is required to avoid the risk of silicone fracture.

On the other hand, silicone with higher Shore hardness values tends to be firmer, less elastic, and more resistant to deformation. It poses challenges when it comes to demolding small, delicate molds and castings, and can even lead to fractures and damage. However, such silicone is well-suited for concrete casting applications, as it offers higher wear resistance and tear strength, which are characteristics that softer silicone materials lack.