The Shore hardness scale is a device used to measure the hardness of materials. Hardness is a measure of a material's resistance to indentation, and this type of measurement is crucial for understanding material properties. Having hardness values allows us to better understand which material is most suitable for specific projects.

ASTM D2240 is the globally recognized ASTM International standard method for measuring the hardness of rubber materials using a hardness tester device. This ASTM standard covers 12 types of hardness measurement devices, all of which are designed to test the indentation depth in test samples.

shore durometer

shore durometer

1. Types of Shore Durometer

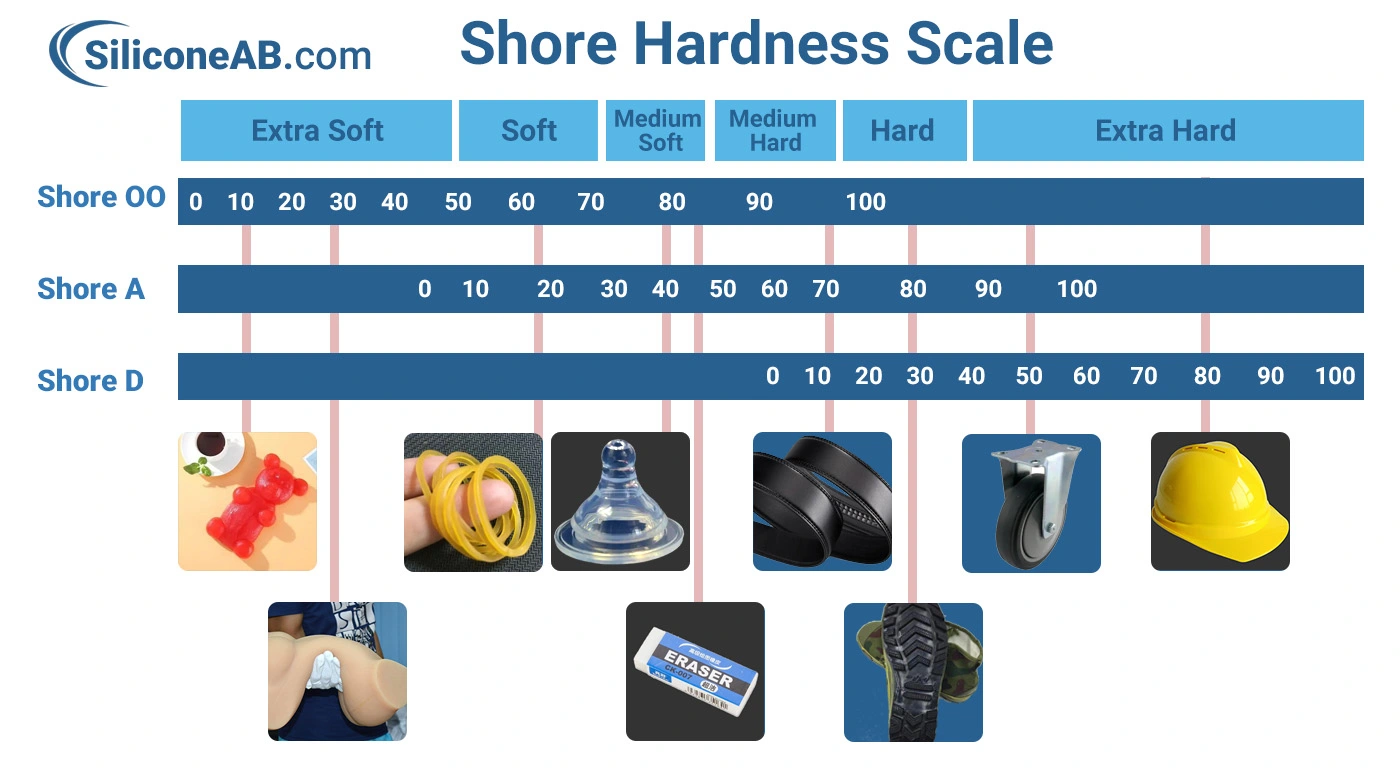

Currently, there are approximately 15 different Shore hardness scales available in the market. Each Shore hardness level ranges from 0 to 100, with 0 representing the softest material and 100 representing the hardest material. The most commonly used Shore hardness scales are Shore OO, Shore A, and Shore D. Here are the measurement contents for these three hardness scales:

1. Shore OO Durometer

The Shore OO hardness scale is commonly used to measure the hardness of very soft and elastic materials, such as gels, lightweight foams (silicone foam), and highly elastic rubber.

shore OO durometer

shore OO durometer

2. Shore A Durometer

The Shore A hardness scale is commonly used for measuring flexible mold rubber materials. This series includes most rubbers, ranging from extremely soft and elastic rubbers to high-hardness rubbers with minimal elasticity. It also assesses semi-rigid and moderately flexible non-rubber plastics.

shore A durometer

shore A durometer

3. Shore D Durometer

The Shore D hardness scale is specially designed to accurately measure the hardness of extremely rigid rubber materials, as well as semi-rigid and rigid plastics. It is commonly used to gauge the hardness of polyurethane casting resins, construction workers' safety helmets, PVC pipes, and other rigid plastic materials.

shore D durometer

shore D durometer

2. Shore Hardness Conversion Table

The following Shaw hardness conversion table is provided for the convenience of discussing materials with a common reference point. However, it is important to note that the hardness values listed are approximate and should only serve as a guide for selecting hardness testers. The most accurate method for ensuring the correct product selection is through physical testing conducted by end-users. Please be aware that this table is intended for reference purposes only and should not be employed in formulating specifications.

shore hardness scale

shore hardness scale

| Shore A | Shore B | Shore C | Shore D | Shore 0 | Shore 00 | IRHD |

|---|---|---|---|---|---|---|

| 100° | 85° | 77° | 58° | - | - | 100° |

| 95° | 81° | 70° | 46° | - | - | 95° |

| 90° | 76° | 59° | 39° | - | - | 90° |

| 85° | 71° | 52° | 33° | - | - | 85° |

| 80° | 66° | 47° | 29° | 84° | 98° | 80° |

| 75° | 62° | 42° | 25° | 79° | 97° | 74° |

| 70° | 56° | 37° | 22° | 75° | 95° | 68° |

| 65° | 51° | 32° | 19° | 72° | 94° | 64° |

| 60° | 47° | 28° | 16° | 69° | 93° | 62° |

| 55° | 42° | 24° | 14° | 65° | 91° | 54° |

| 50° | 37° | 20° | 12° | 61° | 90° | 49° |

| 45° | 32° | 17° | 10° | 57° | 88° | 44° |

| 40° | 27° | 14° | 8° | 53° | 86° | 39° |

| 35° | 17° | 12° | 7° | 48° | 83° | 35° |

| 30° | 12° | 9° | 6° | 42° | 80° | 28° |

| 25° | 6° | - | - | 35° | 76° | - |

| 20° | - | - | - | 28° | 70° | - |

| 15° | - | - | - | 21° | 62° | - |

| 10° | - | - | - | 14° | 55° | - |

| 5° | - | - | - | 8° | 45° | - |