When making silicone molds with RTV-2 liquid silicone, bubbles generated during mixing and pouring can affect the quality and appearance of the final product. Using a vacuum pump to defoam liquid silicone is an effective method to ensure that the silicone cures without bubbles. This article will detail how to use a vacuum pump to defoam liquid silicone, helping you create bubble-free silicone molds.

Step 1: Preparation

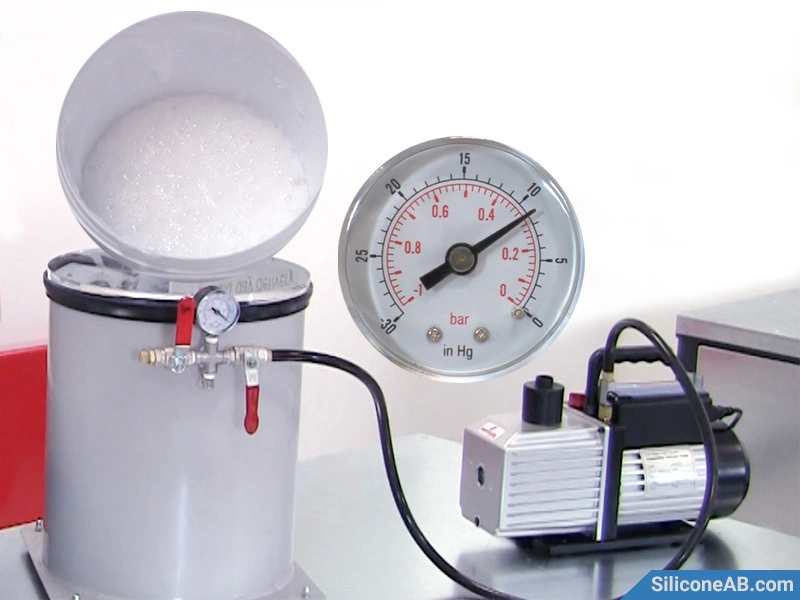

Place the container holding the liquid silicone into the vacuum chamber and seal the chamber with the lid. Note that when vacuuming, the liquid silicone will expand to 3-5 times its initial volume, so the mixing container must be large enough to accommodate the rising air.

Step 2: Start the Vacuum Pump

Slowly turn on the vacuum pump and gradually reduce the pressure in the vacuum chamber. Within a few seconds, you will see a large number of bubbles rise and burst from the liquid silicone. During the vacuum process, do not reach the maximum vacuum level all at once; adjust gradually and observe the state of the liquid silicone. Rapid vacuuming can cause the liquid silicone to boil vigorously and overflow the container.

Step 3: Repeat the Process

During the vacuum process, observe the state of the liquid silicone. By repeatedly closing and opening the valve to control the pressure in the vacuum chamber, allow bubbles to rise and burst.

Step 4: Maintain the Vacuum State

When the bubble rise becomes stable, continue to maintain the vacuum state for a few minutes to ensure all bubbles are removed. The defoaming time varies based on the viscosity and volume of the silicone, generally taking about 5-15 minutes.

Step 5: Restore Atmospheric Pressure

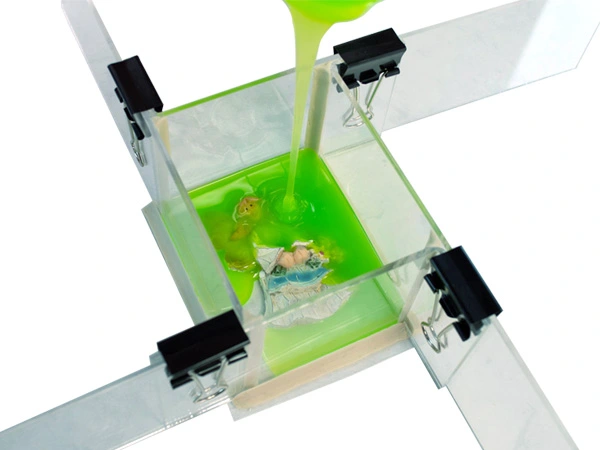

After confirming that the bubbles have been completely eliminated, slowly open the vacuum chamber’s vent valve to gradually return to atmospheric pressure. Then, open the vacuum chamber lid and remove the defoamed liquid silicone for subsequent operations. This process should be done slowly to prevent the silicone from overflowing or forming new bubbles due to sudden pressure changes.

By following the above steps and precautions, you can ensure a smooth defoaming process for the liquid silicone, effectively removing bubbles generated during mixing, and creating bubble-free silicone molds, thereby ensuring the aesthetics and quality of the final product.

Conclusion

Mixed RTV-2 liquid silicone contains numerous bubbles at atmospheric pressure, but after a few minutes of vacuum treatment, the bubbles almost completely disappear. The final cured silicone mold surface is smooth with no bubble marks. This process demonstrates the efficiency and practicality of vacuum pump defoaming.

Video Tutorial

To help you better understand the process, here are some video tutorials on using a vacuum pump for degassing liquid silicone:

Through the content above, you should now be equipped with the skills to use a vacuum pump to degas liquid silicone, allowing you to create bubble-free silicone molds. We hope this article has been helpful to you.